Barenbrug Grower Update

October 2023 Barenbrug Grower Update

October 2023 Barenbrug Grower Update

Welcome to the October 2023 Growers Newsletter

Harvest 2023 was a challenge for all involved. Thank you all for your hard work and perseverance in bringing in the harvest. Yields in the UK are down by 12% compared to budget, mainly down to the wet harvest conditions during July and August. In Europe, yields have also been affected by extremes of weather throughout the spring and summer.

Sales in the professional amenity market in the spring and autumn periods have been meeting the budget, with good performance from our amenity distributor network. Looking forward, the outlook for the professional turf market is uncertain, and we could see a pullback in volumes next season with the downturn in the housing market. The agricultural market has been more of a challenge. The wet spring meant growers were restricted with planned new sowings due to the wet spring, and whilst the autumn sales period started well, it tailed off earlier than expected, mainly due to the wet weather conditions and good volumes of silage harvested throughout the season. This has led to stock levels building yet again on an already long position, coupled with high storage costs, interest rate and operational cost increases, thus increasing the stock price of the seed we have in store.

Unfortunately, the long stock position has led to the tough decision to reduce the October Grower Payment for harvest 2023 by 10 -15% over the final price paid in harvest 2022. We are hopeful that next year sales will improve and the market will react positively.

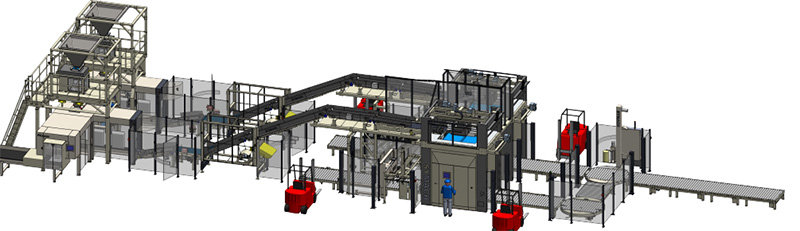

Within this newsletter, there are two articles which I hope you enjoy reading on recent investments we have made in our UK business, our new breeding site at Knutsford and an update on a new automated packing line which we are currently installing at our Bury St Edmunds site, which will add more mixing capacity and reduces the amount of manual handling compared to our current mixing process.

Richard Turner

Seed Production Manager

As you may be aware, Barenbrug global have chosen to extend and enhance their breeding capabilities by establishing a Forage Breeding Station here in the UK.

Located at Knutsford, the site, which covers 59 ha and is owned by the crown, was chosen due to the climate and annual rainfall totals. Plans have been put in for the development of two buildings, with one to be converted into a farm office and the other, a workshop. This work is anticipated to be complete by summer 2024.

The site is overseen and directed by the Barenbrug Global Research Director and managed on a day to day basis by Neil Haynes, our new Assistant Breeder. Neil has been working hard on establishing and maintaining trials, both for Forage and Amenity varieties since the beginning of the year, including planting 6000 plants (pictured) by hand in a couple of days! This is now the sites second season of plantings.

We are looking forward to seeing the site develop and benefiting from the tailored UK breeding.

As you may be aware we are upgrading our mixing and packing facility at Bury St Edmunds, a very exciting time for all staff within Barenbrug UK and the Watson Seed Group. We wanted to update you on how we got here and what is ahead for us.

Why are we upgrading?

Back in June 2020 we undertook several operational studies in relation to our manufacturing capacity and our plans for growth, H&S requirements including staff safety, and staff upskilling.

After discussion with the Barenbrug board it was agreed we would investigate upgrading our current machinery to fully automated lines. This entailed further studies, functionality designs, scoping the works, finding the most suitable companies to partner with and several trips to our sister company in France who have also recently upgraded their facilities to gain understanding of machinery available that encompasses the requirements of the grass seed to market regulations.

In May 2022 the Barenbrug Board signed off the automation project. This means Barenbrug have invested a huge £2.2m into Barenbrug UK with this project, in addition to the roof replacement we completed back in January of 2021, signalling their commitment to the UK business and marketplace.

Our chosen partner for the automated lines is Symach BW Filling and Palletising, who have a wealth of knowledge in palletising. We have enlisted local support for the remaining integration requirements, such as civils works.

What will this look like?

Our BSE facility now has a premix station that uses suction vacuums to move bags from pallets eliminating manual handling, seed distribution platforms that make the emptying of the seed bags more ergonomic and stainless-steel seed hoppers, which are light and stackable, that will be used to fill the blenders in the production process. Our current bulk mixers being integrated into new filling and palletising lines.

What does this mean for Barenbrug UK going forward?

Our investment means the safety of our warehouse team has now increased with the reduction in manual handling. We are also investing in training our team members to provide them with the right skills to support this new way of working. For instance, we have one team member who is training to become an engineer and another who will take the lead in H&S in what is a now a more complicated environment.

The new machinery will increase our capacity significantly - we will be able to run twelve 20kg bags per minute through the automated system! When working manually we could run one bag per minute.

As a leading grass seed house, breeding the highest quality grass, and working with dedicated seed producers, we carefully select our merchant partners.

Our partners are some of the most respected companies and our extensive knowledge of UK Agriculture & Sport means we’re able select and work with the best. Our partners’ support allows us to continue and develop our vital work. We place great value on the relationships we have with them and who share our priorities and support our work.

The latest focus on grassland aims to help farmers grow their future with grass, with knowledge exchange, a grass clinic and regular updates via BarTech - helping all farmers sustain farm resilience by maximising homegrown.

Meet the UK Seed production team